Slot Die Coating Design

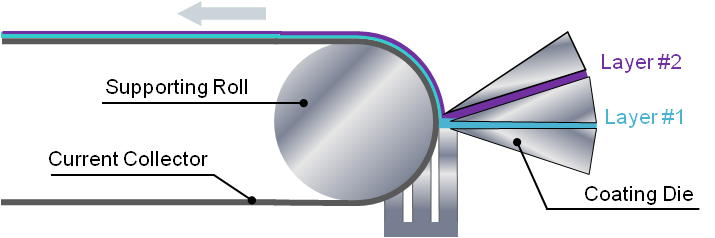

Slot-die coating is a noncontact technique in which solution is pumped from a syringe to the well-defined slit of a slot-die head unit at a defined pump rate (A in Figure 1). In the slot-die coater used here, the die head is fixed and the substrate is passed underneath at a set speed. The direction of substrate is indicated (B in Figure 1). A good example is the design and manufacturing of a slot die for fluid coating operations. The basis of this pre-metered system is that there are two die body halves that are held together to form a slot for fluid to be deposited on a substrate.

Overview

High precision slot die coatings (extrusion coatings) are often key to the successful development and manufacturing of thin film dependent devices. Thin film coating operations may be repeated throughout the product development cycle and represent a key part of the manufacturing process for many microelectronics applications. nTact utilizes its technology and system design experience to develop high-performance slot die coating equipment used for the development and production of a variety of microelectronics and thin film applications.

Applications

Flat Panel display

Flat Panel Display technology has transformed the way people live their everyday lives. This not only includes television screens and computer monitors, but also the vast array of mobile devices such as PDAs, smart and cellular phones, cameras, GPS systems, portable media players, etc. available in the market today.

READ MORE >>

Solid State Lighing

Lighting accounts for approximately one fourth of the total electricity consumed in developed countries. Solid-state lighting uses light-emitting diodes (LEDs) or organic light-emitting diodes (OLEDs) instead of incandescent bulbs

READ MORE >>

Photovoltaic

nTact’s cutting-edge extrusion technology and equipment is being applied to the development of photovoltaic (PV) devices, thereby sustaining an industry which is expected to grow to $116.5 billion by 2019.

READ MORE >>

Smart Glass

Slot Die Coating Head Design

According to a leading clean energy research firm, the use of smart glass as a material in building and construction around the world is set to soar throughout the remainder of the decade as building owners seek to reduce heating and cooling costs by making buildings more energy efficient.

READ MORE >>

Organic, Printed and Plastic Electronics

Companies are diligently working to mass produce products made of flexible, resistant and lower cost materials. A new generation of products including flat panel displays, OLED lighting, RFIDs, flexible batteries and Organic Thin Film Transistors (OTFT) are being produced on flexible plastics such as polyethylene (PET and PEN) as well as stainless steel (SST) and other metal foils.

READ MORE >>

Other Applications

nTact’s proprietary extrusion deposition technology is being used for a variety of emerging technology applications including back-end Semiconductor applications, MicroElectroMechanical Systems (MEMS), Polymer Batteries, RFID’s, as well as Nano and Biotechnology and various other Printed and Organic Electronics applications.

Coating Matters Slot Die Design Considerations

Slot Die Coating Designs

- Published: July 02, 2013

If you'd like to hear from Mark Miller's own lips rather than read his column titled, 'Coating Matters Slot Die Design Considerations,' click on his podcast below:

It’s always good to have a perspective from all areas of a business. In the world of manufacturing, an engineer learns a lot by getting out on the shop floor and turning some knobs. It is also helpful for the manufacturing engineer to have an appreciation of the physical and functional limits of the equipment. This insight can be garnered by engaging in a dialogue with the vendor in question, especially if you have access to the individuals who are involved in the design of the equipment. This design perspective will help lead front line manufacturing projects as companies look to improve efficiencies and drive down production costs.

A good example is the design and manufacturing of a slot die for fluid coating operations. The basis of this pre-metered system is that there are two die body halves that are held together to form a slot for fluid to be deposited on a substrate. The opposite end of this slot is where the fluid is fed in and distributes along a manifold (or flow chamber).

The goal of the manifold is to place the fluid exiting the slot at a consistent velocity so the flow phenomena is predictable when interacting with the substrate. The interfacial chemistry of the fluid and substrate are enough to understand without having to deal with irregular fluid vectors exiting the slot die.

What is awesome about the physical capability of the slot die is that the manifold can be designed for fluids ranging from 1–500,000 cP and still perform as required for product performance. Remember, however, that one manifold cannot coat this entire range! One slot die manifold works for a “family” of fluids within a smaller range of shear viscosity. I am pointing out the robustness of the technology, not the capability of one piece of equipment.

The other amazing characteristic of the slot die technology is the ability to coat from any position around a substrate—horizontal, vertical, above, below…. Because the slot die is a closed system, what goes in comes out, and stopping the pump stops the flow of fluid to the substrate. So if you have heard of curtain coating, this is simply a slot die coater arranged to drop a fluid curtain down from a height, while draw coating is positioning a slot die in a horizontal arrangement farther away from the substrate than in a typical proximity arrangement.

So what can you learn from a slot die designer that will help you in your roll-to-roll manufacturing process? First of all, the slot die has a capability within the rheology range for which the die was defined. This may be a couple thousand cP for some fluids, while only a handful of cP for other fluids.

There are some critical surfaces that define the coating capability with the slot die. These include lip design, lip gap, offset of the die bodies, attack angle, die to substrate gap, and precision of flow surfaces (both inside and out). The boundary conditions of these factors, in addition to the temperature, pressure, and surface energy of the fluid and substrate, predict the flow behavior of the slot die. With this knowledge, an experimental design can be developed around these factors and a coating window established. And you thought the vendor was useful just when you wanted to buy something!

If you can find a vendor who has also lived this life of having perspective from the manufacturing side in addition to the equipment manufacturing side, you have found a very valuable resource indeed. With process-oriented and knowledgeable vendors, you can collaborate on projects to analyze coating defects, develop equipment and process solutions, and impact the bottom line of your business with increased efficiency. Collaboration is key!

Roll-to-roll coating industry expert Mark Miller, owner of Coating Tech Service, has 14+ years of slot die coating experience and troubleshooting. He is the author of PFFC's Coating Matters column. Contact him at 715-456-9545; This email address is being protected from spambots. You need JavaScript enabled to view it.; www.coatingtechservice.com.

Please enable JavaScript to view the comments powered by Disqus.